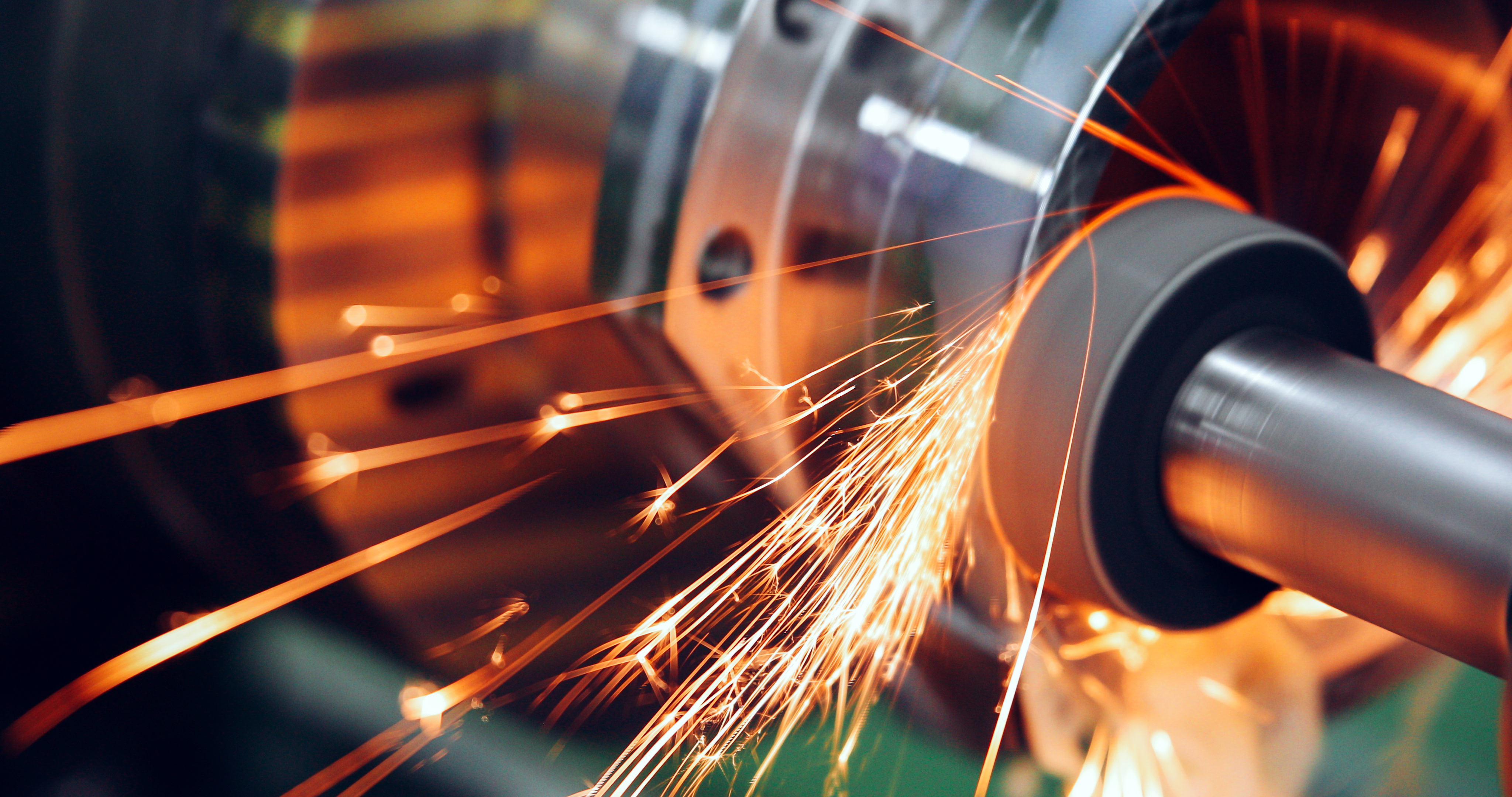

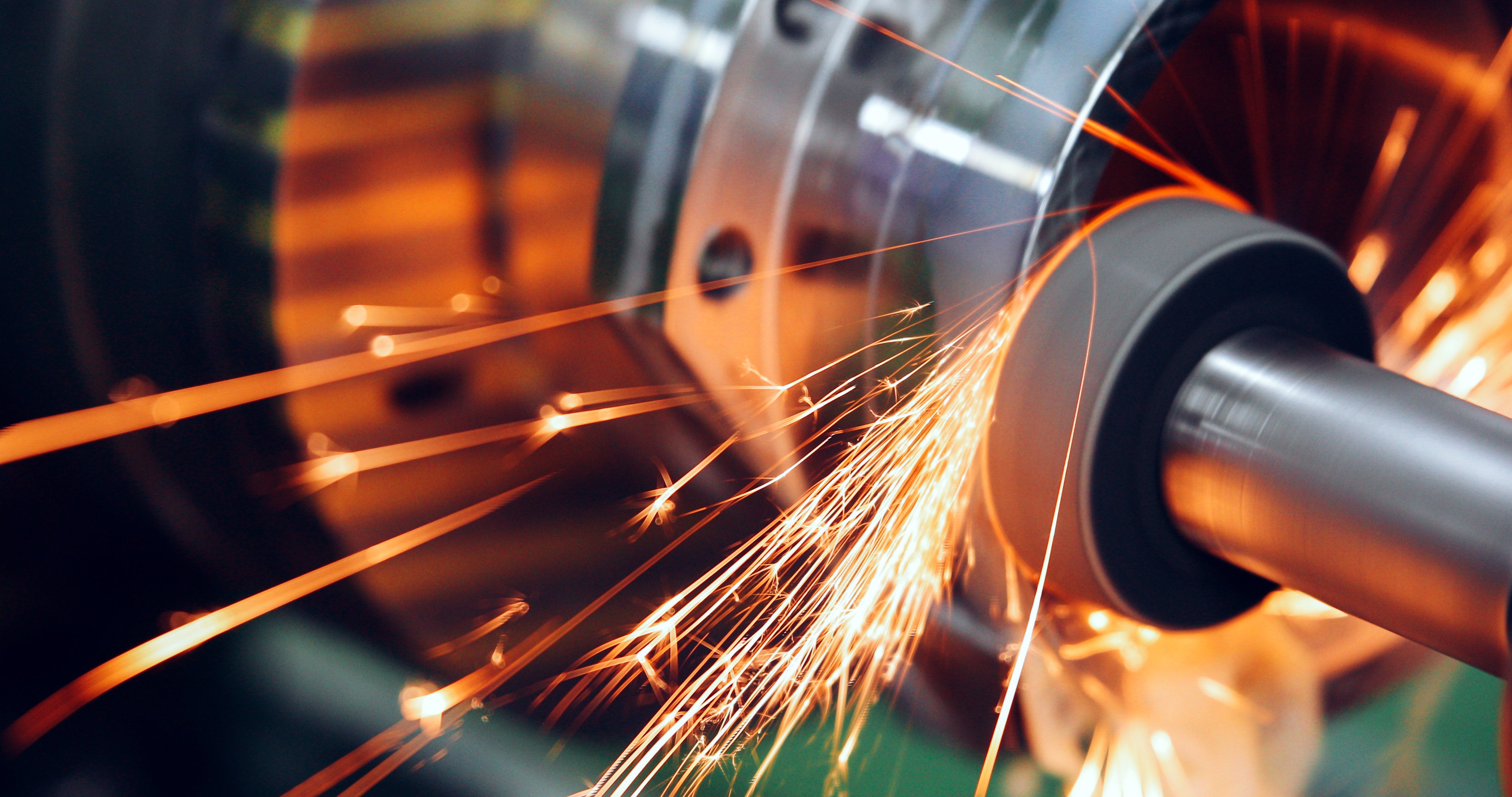

What is precision grinding?

Materials that have relatively small surfaces often require precision grinding to achieve a high degree of flatness and a high degree of surface finish. Traditionally, it is used as one of the final machining processes on a part. Precision grinding is just that exact. It is used for applications requiring tolerances of up to +/- 0.0001" and can achieve surface finishes of around 10 RMS.

What type of parts require precision grinding?

It is primarily tiny metal parts such as the components found in many modern electronic devices that require precision grinding. Conversely, there are several larger parts that also require grinding including those commonly used within aerospace instruments, medical devices, and bladed implements, in addition to scientific instruments. Most precision grinding projects can be adapted to accommodate a wide range of different parts' exact specifications.

What are the different types of grinders?

There are several different types of precision grinding.

Horizontal Spindle Surface Grinding: This method uses an abrasive wheel rotated at tremendously high speeds and then brought into contact with a flat surface of a part.

Cylindrical Grinding: This is a similar process to horizontal spindle surface grinding. The difference is it is used to grind round objects. As such, it requires a different work-holding device. The abrasives used in the cylindrical grinding process can be dressed to help shape the part.

Some abrasives that are most often used for horizontal spindle surface grinding and cylindrical grinding include zirconia alumina, silicon carbide, and aluminum oxide. Depending on how it's being used, lubricants may be used to keep the high temperatures down, during the grinding process.

What are the different grinding applications?

Several other types of lesser-known precision grinding include centerless grinding, creep-feed grinding, and internal diameter grinding. Their applications include:

- Stampings

- Shafts

- Bushings

- Machine components

- Pistons

- Cylinders

- Molds and Dies

Why is precision grinding important?

Precision grinding is used for various products that vary in size, both large and small. This process can accommodate incredibly exact individual specifications. This accuracy is essential in various industries with little to no margin for error, including medical devices, scientific instruments, and aerospace mechanisms.

As modern electrical devices continue to get smaller, the metal components located within them must decrease in size too; therefore, requiring precision grinding for manufacture. Although there are other alternative methods and techniques, accuracy is guaranteed. It is a more cost-effective production method.

Precision grinding can also increase productivity. It's an easy job to oversee, which means quality control can be consistently maintained while operating an efficient manufacturing process. Additionally, it produces an excellent surface finish and a high-quality end product.

For more information on SPR's precision grinding and tooling services, contact us.