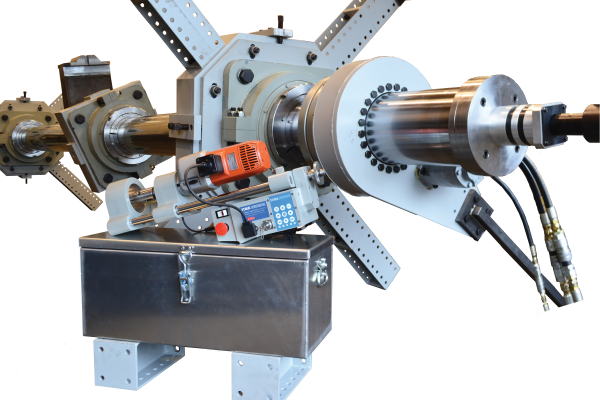

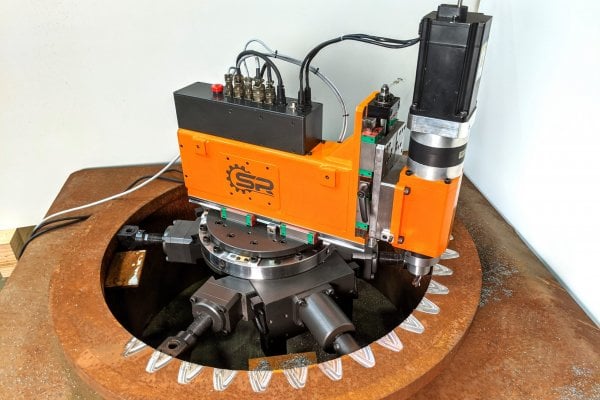

Introducing the Giotto Orbital Welder TIG Orbital Welding System

The Giotto Orbital Welder is a TIG orbital welding system intended for use on tubes between 10 and 51 millimeters in diameter. The robust, hand-held device provides technicians with a simple, safe, and efficient means of combining tube to tubesheet edges on heat exchangers.

While welding machines come and go, this one, in particular, has many unique characteristics to note. The first is the accuracy of the orbiting head itself; preset angles maintain the geometric requirements of whatever task is at hand to ensure high-scale repeatability.

Operators have complete control over the electrode's two-dimensional position and torch as they weld, allowing them to move into any angle or radius easily. This helps enhance the quality of their work and allows for more consistent results every time.

A DC motor and absolute encoder power the Giotto Orbital Welder's automated system, which controls the head's speed and direction. This ensures a smooth weld while avoiding any unnecessary vibration or jerking movements that can cause unevenness in the joint.

Filler wire can sometimes be challenging to feed, but this tube welding tool is made with ease of use in mind. Its back-end driving system is cased in a transparent material, allowing operators to watch things move in real time. And while the AMI welding head can be left and observed as is, there's also a protective cover that protects users from errant sparks and splatter.

This kind of controlled power is a game-changer for teams wanting to finish more work in less time. With anti-dazzle protection, multiple technicians can continue working on the same project simultaneously without worrying about eyesight protection.

Whether you have a small job to finish or multiple at hand, rest assured the Giotto Orbital Welder can handle it with class. The tube welding machine has a built-in water cooling system that maintains head performance over long periods.

There's no need to worry about overheating or inconsistent results - with Giotto Orbital Welder, you're guaranteed a clean and smooth finish every time.

- The orbital axis reel is consistent in flow and rotation, increasing weld accuracy

- Anti-dazzle protection makes it easier and safer for more people to work in the same space

- The Giotto Orbital Welder's two-channel, 256-pulse digital encoder ensures uniformity and repeatability

- No need for service wrenches with the Giotto Orbital Welder's simple electrode replacement process

- Singularly-supplied key works in all operational directions and angles

- The robust build is sure to last throughout long-term and consistent use

The QR codes and corresponding titles presented below link to various documents you'll want to read before using the Giotto Orbital Welder.

Product Catalog

Learn more about the Giotto Orbital Welder's functions, models, features, and available accessories.

Take a look at this video for an in-depth review of what the Giotto Orbital Welder offers.

- Orbital welding is a relatively specialized process only specific industries use in particular contexts. Those involving heat exchangers are the most common, as technicians require the help of a tube cutting machine, expander, and tube to tubesheet welder to install new tubes during maintenance.

- You may see a TIG orbital welding system like the Giotto Orbital Welder used by teams that provide maintenance and support for high-demand applications like food processing, pharmaceutical production, chemical manufacturing, oil refining, nuclear energy production, aerospace, and other critical industries that rely on heat exchangers.

- This orbital welding equipment ensures that high-pressure and heat-resistant tubes are fitted precisely and securely.

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)