Hydrol 20.1 Hydraulic Single Head Tube Rolling System

The Hydrol 20.1 caters to smaller-scale projects with limited expansions and lower budgets. Despite its affordability, this hydraulic rolling system delivers exceptional performance and efficiency. Its key features make it a valuable entry-level option for tube rolling tasks.

The system's robust construction significantly reduces the need for maintenance, ensuring reliable and uninterrupted operation. This durability also contributes to the excellent quality of the rolled tubes, guaranteeing consistent and precise results.

The Hydrol 20.1 is lightweight yet powerful, making it suitable for accessing hard-to-reach areas without compromising performance. Its noiseless operation adds to the convenience and user experience.

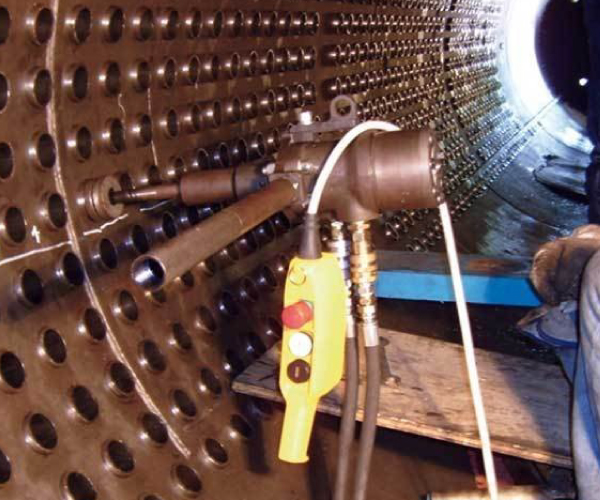

This equipment is particularly well-suited for applications in boilers and cracking furnaces. Its reliability and efficiency enable users to confidently accomplish their tasks, knowing the system will meet their expectations and complete the job correctly.

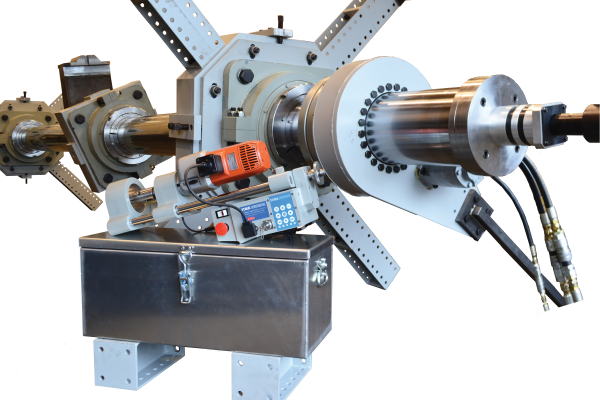

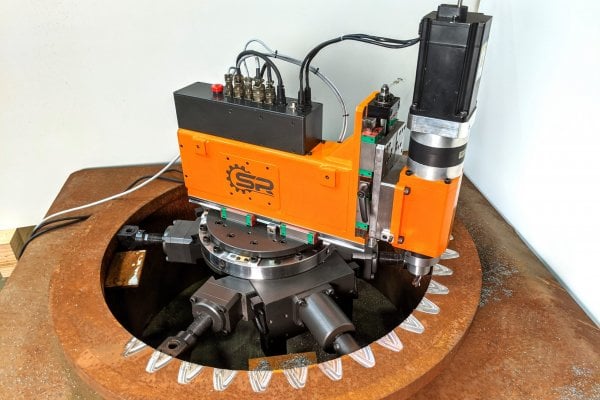

The Hydrol system includes several components to facilitate its operation. This comprises the Hydrol 20.1 control and power unit and the central control hub. The HM hydraulic rolling head, selected based on the desired working torque, has a carrying case for easy transportation and storage. The HR fixed connector and two high-pressure hydraulic hoses and couplings ensure a secure and efficient connection.

A portable pushbutton control panel with a 10m cable also allows manual remote control. The system incorporates an air or oil radiator to maintain optimal operating temperatures.

The Hydrol 20.1 enables accurate tube rolling operations by maximizing efficiency and offering precise control. Its impressive force generation capability, even in challenging or confined spaces, ensures that projects can be completed quickly and with satisfactory results.

Investing in a hydraulic tube rolling system from Hydrol, with its sturdy construction and superior performance, will save time and money. The system's ability to deliver excellent tube rolling results ensures that users can achieve their goals effectively and efficiently.

For those seeking a reliable and cost-effective solution for tube rolling machines, the Hydrol 20.1 is an excellent choice.

- High power and torque for smooth roll-forming operations

- Accurate measurements and level surface finish

- Extremely durable, compact, and lightweight design reduces the need for maintenance and repairs

- Cost-effective solution

- Noiseless

- Easy to install and operate

- Highly reliable in all conditions

- Powerful hydraulic drive

Scan the QR codes below to download the user manual and other brochures for the Hydrol 20.1

Product Catalog

Browse the Hydrol 20.1 control and power unit product catalog to learn more about its features, capabilities, and use cases.

Watch the video below to learn more about the Hydrol 20.1 hydraulic single-head tube rolling equipment's specifications and use cases.

- The Hydrol 20.1 control and power unit is utilized in applications across various industries, offering versatility and efficiency for various tasks.

- The Hydrol 20.1 is well-suited for shaping and forming tubes in automotive bodywork fabrication. Whether creating complex curves or bending tubes to fit specific vehicle components, the machine's torque control and precision ensure consistent and accurate results.

- The aerospace industry also uses the Hydrol 20.1 to roll tubes during aircraft wing construction. It facilitates the production of smooth, aerodynamic shapes, meeting stringent quality requirements and ensuring structural integrity.

- Beyond specific industries, the Hydrol 20.1 is a valuable tool for general metal shaping tasks. Whether for artistic purposes, architectural fabrication, or custom metalwork, the machine's adjustable guide roller and quick change system allow easy adaptation to different tube diameters and wall thicknesses.

- The Hydrol 20.1 is useful in the heating, ventilation, and air conditioning (HVAC) industry. It can be employed to shape and manipulate tubes for ductwork, allowing for efficient airflow and optimal system performance.

- In plumbing and pipework installations, the Hydrol 20.1 ensures the accurate shaping of tubes for various applications. The machine provides a reliable and efficient solution, from bending pipes for water supply systems to forming connections in plumbing fixtures.

- The Hydrol 20.1 offers flexibility, precision, and speed in all these applications. Its adjustable guide roller allows for customized shaping, while the quick change system enables efficient adjustments to different tube sizes and shapes. The machine's ability to achieve accurate results quickly makes it a valuable asset in industrial settings, where productivity and quality are paramount.

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)