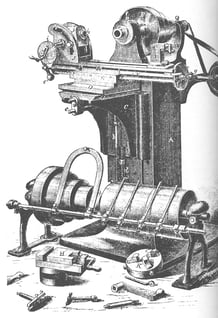

The milling machine was born in 1861 when Brown and Sharpe developed the revolutionary Universal Milling Machine. It completely changed the machining landscape because it could mill complex parts with movement in three different axes. From that point, production took off. Since then, milling technology has developed at lightning speed in a century, and SPR has been at the forefront of this evolution.

The milling machine was born in 1861 when Brown and Sharpe developed the revolutionary Universal Milling Machine. It completely changed the machining landscape because it could mill complex parts with movement in three different axes. From that point, production took off. Since then, milling technology has developed at lightning speed in a century, and SPR has been at the forefront of this evolution.

Today, we have high-accuracy machines that have set the standard for milling precision. Machinists can quickly and accurately machine surfaces with exactness. Not to mention the fact that most milling equipment can be transported to the job site, not only saving time, but money. But if you’re still unsure about the terms used concerning machining equipment, read on for a little bit of clarification.

By Scientific American 1862-12-27, Public Domain,

https://commons.wikimedia.org/w/index.php?curid=4277371

Field Machining Equipment

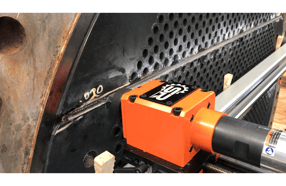

One of the most significant advances in the evolution of machining equipment is the ability to perform field machining. That is machining at the job site, and it’s done just as precisely on the worksite as it is done in the machine shop. The days of having to dismantle the piece of equipment, load and transport it to the shop, dismantle it some more, repair it, and transport it back to the job site are gone. Versatile and modular is how many describe today’s field machining equipment that includes everything from line boring machines, to OD mount flange facers. In-the-field services might consist of turning, milling, drilling, grinding, honing, boring, and lapping. Companies such as SPR carry these items and many more in their inventory. They are regularly in stock, well maintained, and available for quick delivery to your job site. Today, it is just as common to see the machining done at the job site as it is in the shop.

One of the most significant advances in the evolution of machining equipment is the ability to perform field machining. That is machining at the job site, and it’s done just as precisely on the worksite as it is done in the machine shop. The days of having to dismantle the piece of equipment, load and transport it to the shop, dismantle it some more, repair it, and transport it back to the job site are gone. Versatile and modular is how many describe today’s field machining equipment that includes everything from line boring machines, to OD mount flange facers. In-the-field services might consist of turning, milling, drilling, grinding, honing, boring, and lapping. Companies such as SPR carry these items and many more in their inventory. They are regularly in stock, well maintained, and available for quick delivery to your job site. Today, it is just as common to see the machining done at the job site as it is in the shop.

Portable Machining Equipment

![IMG_1015[1]-1](https://www.sprtool.com/hs-fs/hubfs/IMG_1015%5B1%5D-1.jpg?width=261&name=IMG_1015%5B1%5D-1.jpg) There is a variety of mobile machining equipment available for use by maintenance personnel in a field environment. They are usually relatively lightweight and easily transportable machine tools. All that is generally required is either a phone call or an in-person visit to your local SPR dealer to rent your equipment. Often, SPR can quickly and easily move the portable machining equipment to your jobsite.

There is a variety of mobile machining equipment available for use by maintenance personnel in a field environment. They are usually relatively lightweight and easily transportable machine tools. All that is generally required is either a phone call or an in-person visit to your local SPR dealer to rent your equipment. Often, SPR can quickly and easily move the portable machining equipment to your jobsite.

Typically, these portable machine tools are powered by either a hydraulic or pneumatic motor from an outside source. They are placed in two different categories either as a finishing tool (grinders, polishers, sanders) or cutting tool (straight and angled hand drills, metal sawing machines, and metal cutting shears). As is typical of any of SPR portable machining equipment, should you have questions or concerns, we are here to answer them.

Machining - The Choice is Yours.

Whether you chose portable, on-site, or field machining equipment, SPR can help. All these services have a common link in that the machining equipment comes to you: the client. By choosing SPR’s portable, on-site, or field machining equipment, you’re assured the best tools and customer service in the industry. SPR is here to help you get the job done right and on time.