- Home

- Line Boring Machines

- 12-36 Line Boring Machine

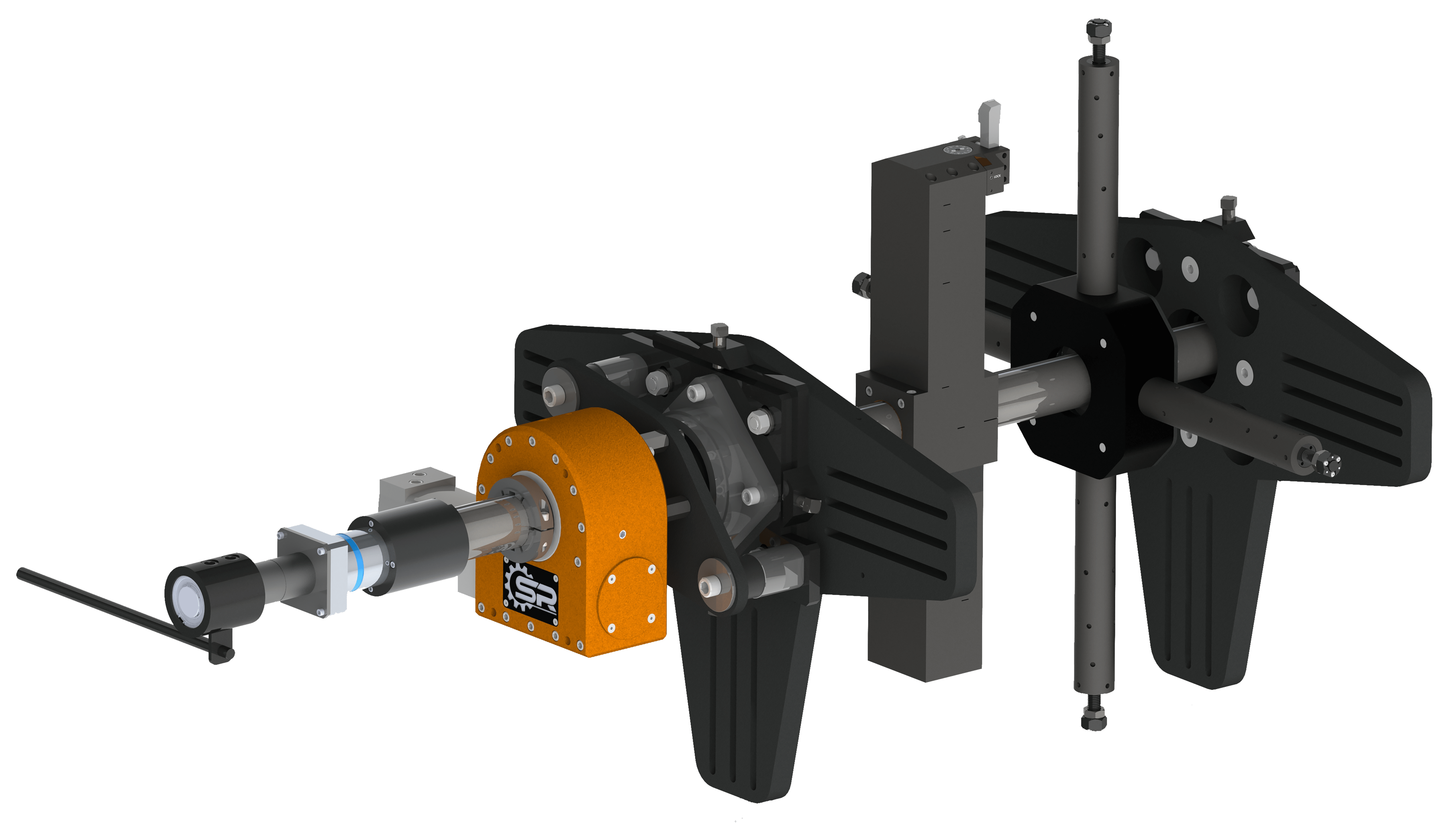

12-36 Line Boring Machine

The SPR York 12-36 portable line boring machine can be set up in several ways depending on the work area. Tack weld plates are provided, but in some cases, you may want to pick up an existing bolt pattern on the workpiece. If so, a special setup fixture would be required and can be manufactured by SPR York Portable Machine Tools.

- Using the bar length chart select the correct length boring bar for the job.

- Attach the three-leg mounting fixture to the workpiece

- Mount the bearings on each end and bolt them to the bearing plates

- Insert the boring bar

- Mount the two halves of the head to the boring bar. Tool head extensions may be required for larger bores. Extensions are provided in the kit

- Center the bar by sweeping the bore. Adjust the bar alignment with the jacking screws on the jacking plate. When the bar is aligned tighten the bearing to the jacking plate to prevent further movement.

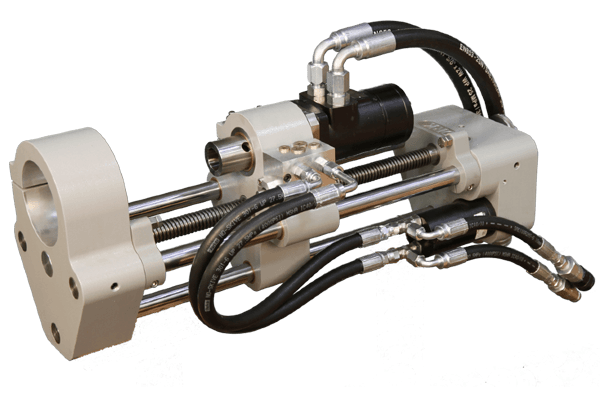

- Attach the feed motor to either end of the boring bar and connect the hydraulic bar drive.

For more information on purchasing or renting, request a quote below.

Advantages

- Boring diameters from 8-36”

- Twin lead screws for balanced feeding

- Variable and reversible feed rates

- Variable and reversible rotation speeds

- X/Y adjustable bearing mounts

.png)