- Home

- InLine Turning Lathes

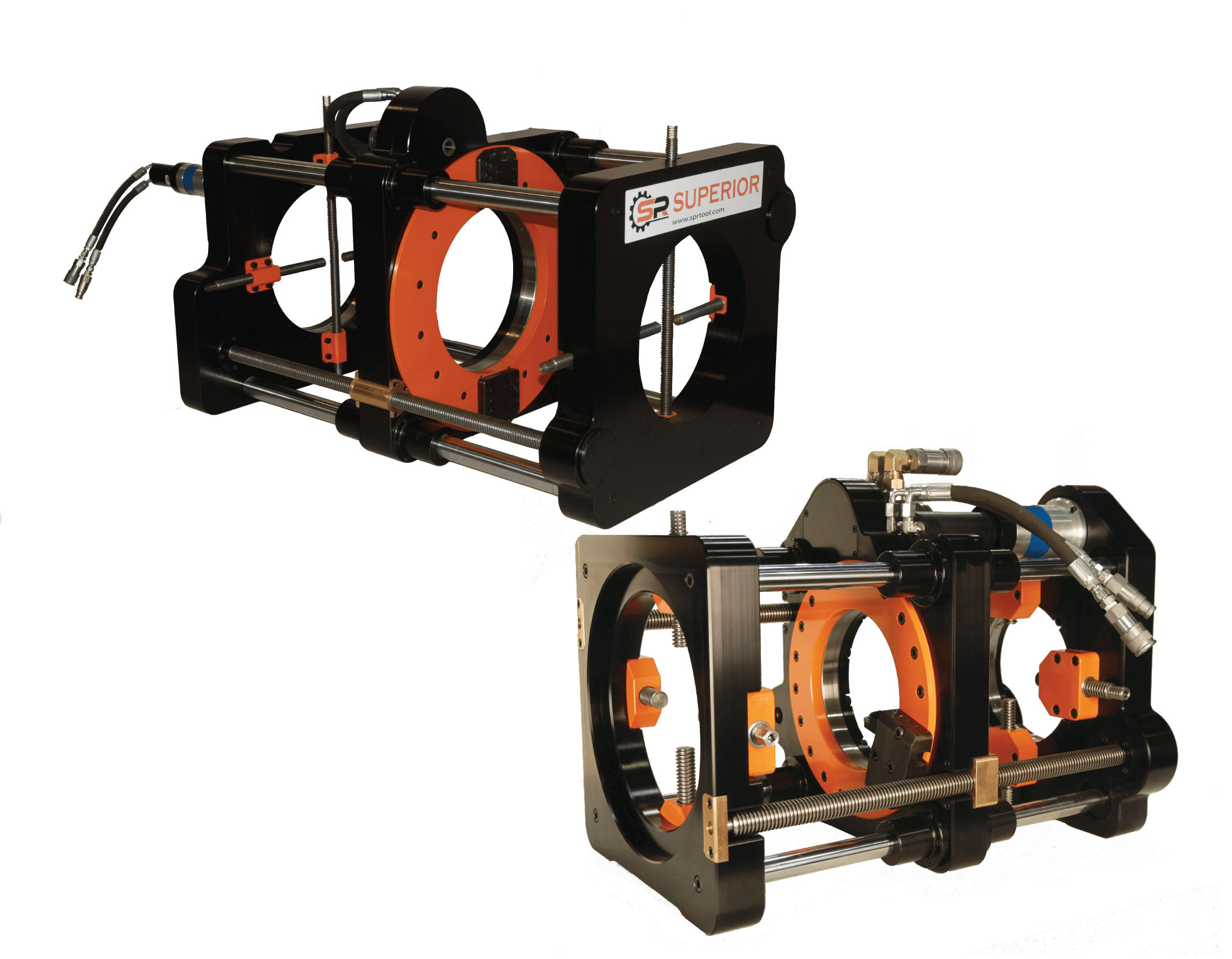

Inline Turning Lathes

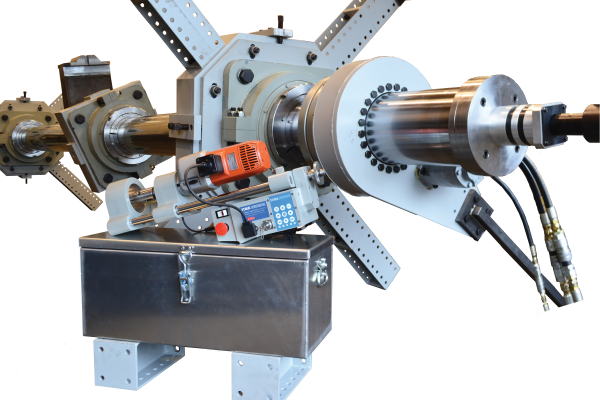

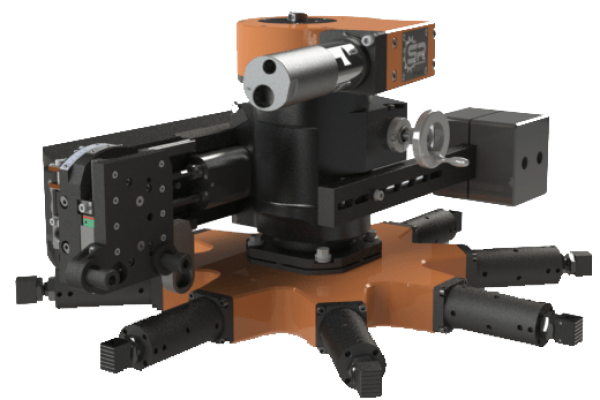

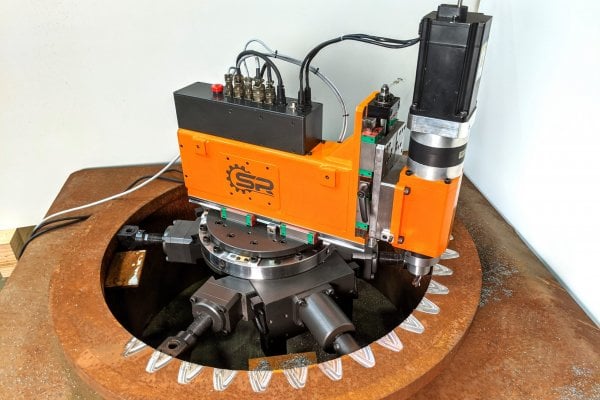

SPR’s Inline Turning Lathes are the perfect tool for onsite resurfacing of large shafts, stub shafts and bearing journals/seats, requiring little disassembly or costly relocation of equipment. These machines run on precision linear guide bearings and are driven by two lead screws for balanced feeding. Both feed and rotation are hydraulically driven with continuous speed control and are independently adjustable while in use. Standard ranges are split into two machines, ILT-1000 (4” to 9.6”) and ILT-1600 (8” to 16”), with custom sizes available for unique applications, including clam shell options. For more information on purchasing or renting, request a quote below.

Advantages

- Diameters from 4-10” or 8-16”

- Features That Measure Up

- Induction hardened chrome guide bars

- Precision linear guide bearings

- Twin lead screws for balanced feeding

- Capable of doing stub shafts or in line turning

- Variable and reversible feed rates

- Variable and reversible hydrostatic rotation rates

- Threading and milling optional

- X/Y adjustable mounting

- Custom sizes for unique applications

- High quality alloys and fittings

- 20ft hoses

.png)

.png)

.png)

.png)

.png)

.png)

-2.png)

.png)

.png)

.png)

.png)