- Home

- OD Mount Flange Facers

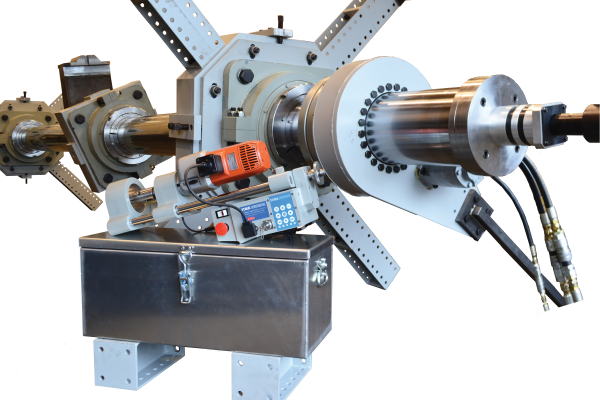

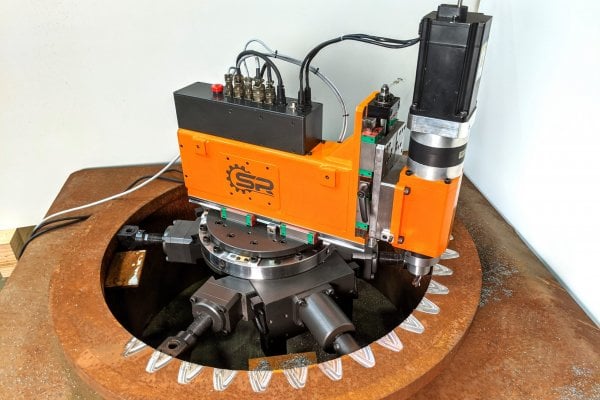

Outside Diameter Flange Facing Machine (ODFF)

Superior’s Steel O.D. Mount Flange Facing Machines are built to deliver performance, precision, and efficiency across a wide range of applications. Each unit is thoughtfully engineered with operator convenience in mind — from design and rigging to packaging — making them easy to transport, set up, and operate in the field. Powered by a durable pneumatic motor, these belt-driven machines feature adjustable cam bearings for accuracy and a precision ball rail slide and compound system that ensures exceptionally smooth travel.

What truly sets our large diameter steel OD flange facers apart is the Hands-Free Automatic Feed. With the push of a lever, the tool advances steadily across the flange surface, eliminating manual feeding and delivering a uniform, high-quality finish every time. This not only reduces operator strain but also boosts productivity, safety, and consistency — key advantages in demanding on-site machining environments. By combining rugged design with smart, operator-friendly features, Superior’s OD Mount Flange Facers provide a faster, safer, and more reliable solution for precision flange facing.

Superior’s O.D. Mount Portable Flange Facers come fully equipped and ready to work, packaged with a ½” tool holder, air motor, oiler, air hose with control valve, and lifting cables for safe and efficient operation. Back-facing attachments are available, giving you greater versatility on the job. Our lightweight Aluminum models are offered in 10”, 13”, 16”, and 20” sizes, while our heavy-duty steel models cover larger applications with sizes ranging from 32” up to 102”. For precision applications, an optional indicator jig is also available. Whether you’re looking to purchase or rent, request a quote today to find the right solution for your needs.

Advantages

- Aluminum Available in 10”, 13”, 16”, and 20” Sizes

- Steel Available in 32”, 42”, 52”, 62”,72”, 82”, and 102” Sizes

- Belt Driven

- Both Radial and Axial feeds

- Manual and Automatic feeds

- All Types of RMS Finishes

- Tool Holder for 1/2” Tool Bits

- Compound Swivels to Machine all Angles, from 0 to 90 Degrees

- Rigid Construction to Maximize Performance

- Adjustable Jaws for Fast 4-Jaw Set Up

- Back Facing Attachments Available

- All Rotating Parts Concealed Behind Solid Cover

- Pneumatic and Hydraulic Motors

- Lifting Cables and Swivel Eyes Provided

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)