The Challenge

Lonny Johns with Mission Tool, a tool and die shop located in Louisville, Kentucky, contacted SPR through a web search. He was looking for a way to repair a 1,500 ton press with a top bed that was bent and needed to be machined to a flat surface. The press is used to stamp out parts and the top and bottom beds must be parallel and flat for consistency.

The Solution

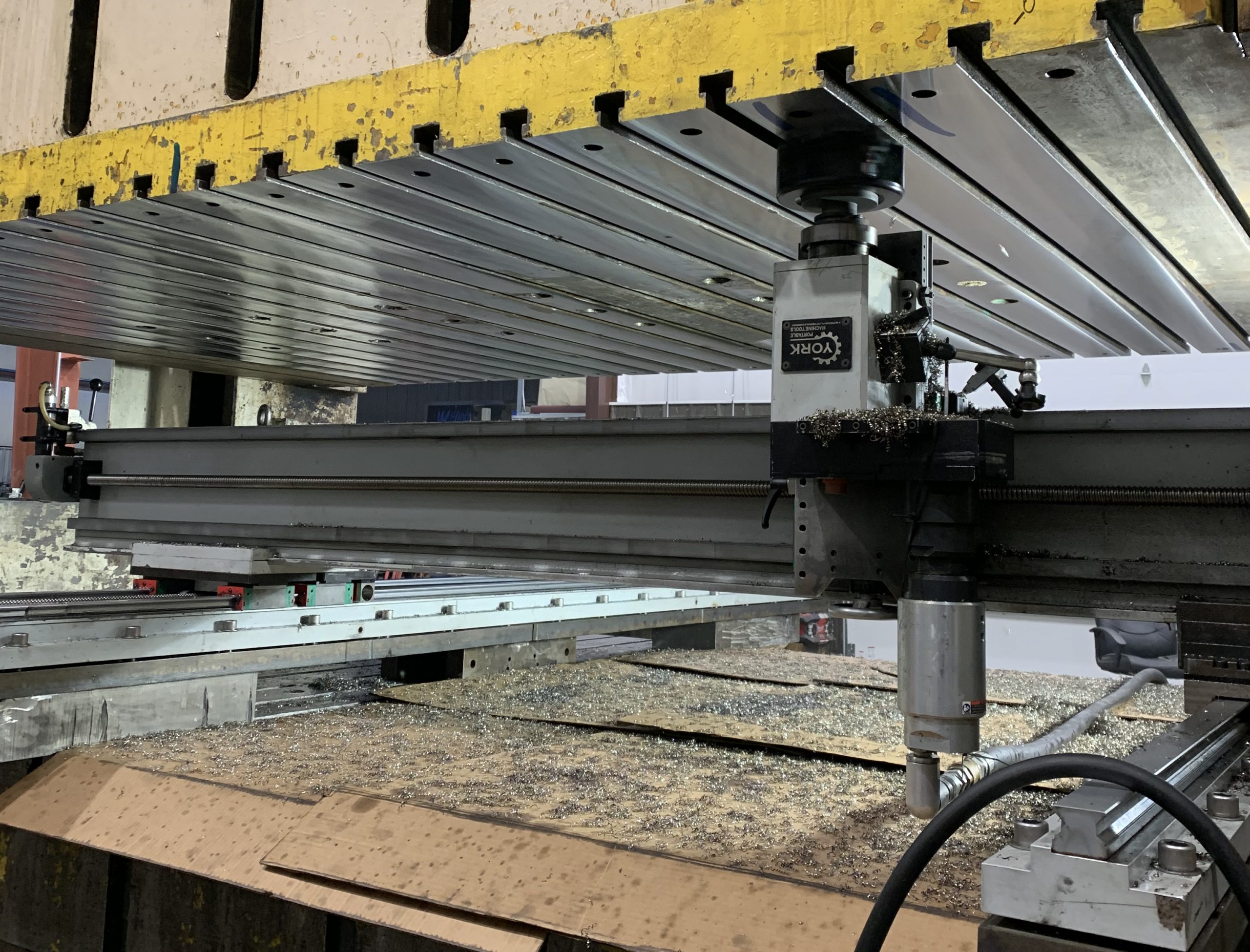

After speaking with Mr. Johns about the challenges he faced with the press, our team suggested the rental of the SPR gantry mill would be the ideal solution. This versatile machine included a 10 ft. linear mill with a 6 ft. gantry arm. Superior invited Mr. Johns and another employee to our Gonzales, Louisiana location to see the equipment and go through a training class on the use of our precision ball screw gantry mill. An actual simulation of the job scope was laid out and the class covered all safety aspects including set up of the machine, estimated machining time, and surface finishes. We also simulated inverting the head and fly cutter to cut upside down and actual cutting with the gantry mill. At the end of the class, Mission Tool was confident that the technical support and rental equipment SPR provided prepared them to proceed with this job.

The Plan

For set up of the machine, instead of using a laser, all measurements were taken using micrometers and a height gage. The gantry mill was set up on the bottom bed of the press and indicated parallel to the bottom bed using the height gage. The head was inverted to cut the bottom side of the top bed. Because of machine restraints on the press, the gantry could machine about 40% of the bed per set up. The first set up and cut was made, then the machine was moved to the other half of the bed and the next 40% was machined. A third and forth set up were used to machine both ends of the bed press where the gantry mill bed could not initially reach, with the mill and angle bracket. All of this machining was done in the inverted position with the head and cutter cutting upside down.

The Results

The amount of material removed was 0.165” on the 8’ x 12’ bed. The surface finish achieved was better than a 16 rms. The final overall flatness after machining was 0.005” over 12’ length. That’s 0.0004” per foot tolerance using micrometers for set up.

Mr. Johns stated, “That’s where SUPERIOR Plant Rentals in Gonzales, Louisiana came into the picture. They have a portable gantry mill with the capabilities to machine inside of the machine straight up. After speaking with their helpful group on the phone, they offered to show me how it worked and came up with a game plan of me visiting in person. After a few hours I felt comfortable that their mill could do the job. It was a lot of work, but the gantry performed great and Superior kept in touch through the whole process in case anything went wrong.”

SPR is continuously providing value-added engineering, training, and operational support. As a team, we have an extensive background in service, unrivaled knowledge of the equipment we rent and sell, and a willingness to go that extra mile for our customers. When you combine those elements, you have a company with a strong commitment to providing superior equipment and customer care.